How to expand EPS Loose-fill Particles

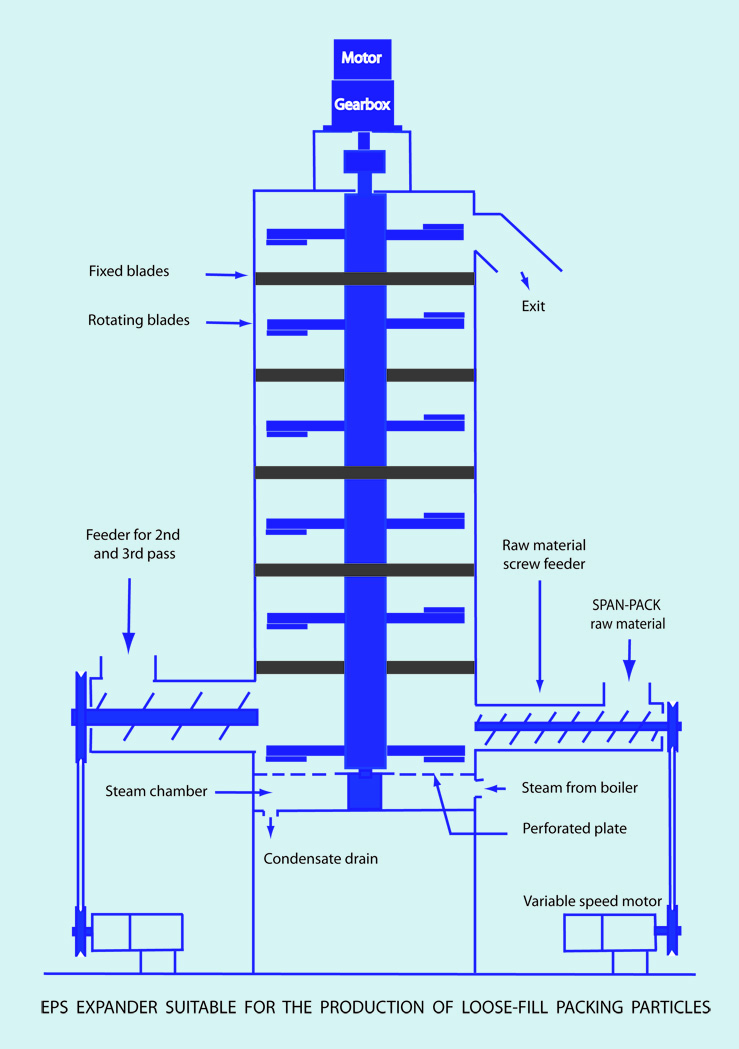

The simplest way to expand our raw material is with a modified classical vertical continuous pre-expander. The same expander used for EPS moldable beads used to produce blocks or molded parts but with two feeding ports instead of one.

Continuous pre-expander:

A continuous pre-expander is a vertical cylindrical vessel operating at atmospheric pressure. For this reason the chamber temperature is limited to 100ºC. The raw material is feed continuously at the bottom of the vessel by a screw feeder and the pre-expanded particles leave the machine through an opening in the top side. Steam is introduced continuously at the bottom (steam chamber with a perforated plate) of the vessel. The screw feed rate, steam pressure and the height of the overflow exit allow control of the density of the particles.

When heating the vessel with steam between 90 and 100ºC and feeding the SPAN-PACK® raw material resin, the polystyrene softens and the vapor pressure of the pentane increases. These two processes cause the beads to expand by up to 70 times their original volume and the formation of the foam structure of closed cells within the beads.